Electronic Throttle Control Failure – A Beginner’s Repair Guide

Has your car recently had issues with rough acceleration or idle, unpredictable engine speed, check engine lights, or throttle response? Have mechanics said it could be a problem with your electronic throttle control system? If so, you’re not alone – thousands of vehicle owners face throttle control failures and getting to the root cause can be confusing.

But what exactly is going on when an electronic throttle body or throttle position sensor fails? And what repair options does a beginner DIYer have?

An electronic throttle control uses electric signals to connect your accelerator pedal to the throttle body and regulate air and fuel flow into the engine. If components sending these signals fail, your engine can hesitate, stall, or even rev out of control. While scary, a thorough diagnosis guides even novice mechanics to an effective fix.

This beginner’s repair guide will walk through:

- How electronic throttle control works

- Common symptoms of throttle failure

- Professional vs DIY diagnosis options

- Necessary replacements like the throttle body or TPS

- Step-by-step instructions guiding you through the replacement process

Gaining confidence in diagnosing and repairing throttle problems yourself saves money and gets your vehicle back on the road safely. Let’s get started!

Table of Contents

Understanding Electronic Throttle Control and How It Works

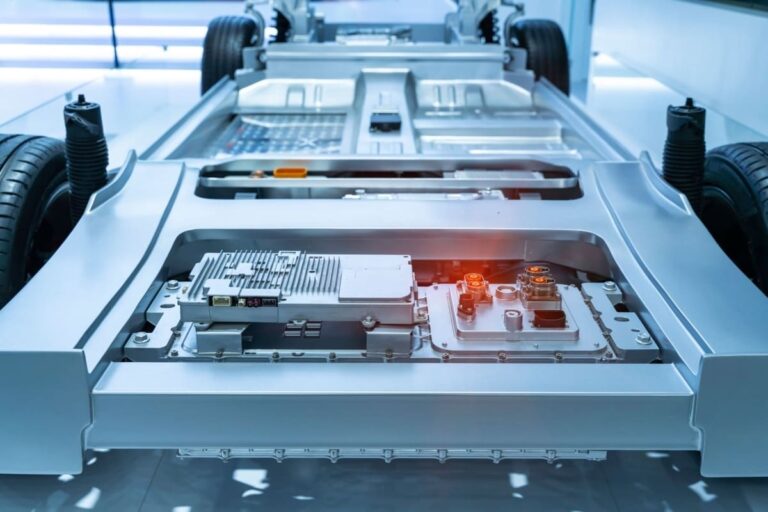

Electronic throttle control (ETC) systems bridge the mechanical connection from your accelerator pedal to the engine with electric sensors and processors telling the throttle how far open or closed it should be.

Here are the key components of electronic throttle control:

- Accelerator Pedal – The gas pedal sensor detects how far you are pushing the pedal and sends an electronic signal indicating pedal position.

- Throttle Body – This component controls air intake based on accelerator pedal position. It contains a throttle valve and throttle plate regulating airflow.

- Throttle Position Sensor (TPS) – This sensor measures the angle of the throttle valve in the throttle body and relays position.

- Engine Control Module (ECM) – The ECM uses data like accelerator pedal position and TPS throttle angle to determine appropriate throttle opening for engine speed wanted by the driver.

When you press your accelerator pedal, the movement triggers a sensor detecting how far it is pushed. This pedal position sensor communicates with your ECM, informing it you want faster acceleration.

The ECM takes in additional data like throttle position, calculated load, and engine RPMs. It computes the optimum throttle angle needed from the data and sends instructions to the electronic throttle body controlling air intake.

The throttle receives signals to open the throttle valve further, allowing more air into the combustion chambers. More air mixes with fuel for bigger combustion events – translating your pedal push into engine power and torque out on the road.

What are Common Symptoms of a Failing Electronic Throttle Body or Throttle Position Sensor?

Problems with electronic throttle control disrupt the communication between your pedal and throttle body. This manifests in engine performance issues like:

Difficulty Accelerating

- Car hesitates when trying to speed up from stop

- Lacking power when merging or passing other cars

Rough Idling and Stalling

- Higher than normal RPMs at idle or idle surging up and down

- Engine stops running during idle at stop lights or signs

Check Engine Light Illumination

- Light comes on indicating trouble code(s) stored for throttle control

- Commonly a P2101 – Throttle Actuator Control Motor Circuit code

Abnormal Noises

- High pitched whining from throttle body itself

- Noticeable clicking sounds from under accelerator pedal

While similar issues can arise from actual engine problems, they often point to replaceable throttle components needing attention to restore performance.

Should you Visit a Professional Mechanic or Attempt DIY Diagnosis?

Noticing potential electronic throttle failure symptoms arises the question – is this repair in DIY territory or best left to professional mechanics?

Factors impacting the diagnosis decision include:

- Your technical skill and repair experience

- Tools available like diagnostic scan tools

- Make/model/year of your vehicle

- Comfort working in cramped engine spaces

Benefits of Professional Diagnosis

Dealerships and trusted local mechanics have specialized equipment, training, and resources helping them zone in on electronic throttle problems. This includes:

- Diagnostic trouble code scanners to read throttle sensor issues

- Access to factory service manuals with throttle testing procedures

- Specialized tools for safely accessing tricky throttle components

- Identifying additional issues like transmission, fuel, or emissions problems

The DIY Diagnosis Option

Thanks to repair information available online, diagnosing throttle issues yourself is also realistic. Scanners reading trouble codes are affordable or rentable and step-by-step testing guides are searchable for most vehicles.

Armed with the proper reference materials and safety precautions, an at-home diagnosis lets you discover:

- If the throttle body, TPS, or both need replacement

- The opportunity to replace components yourself at major cost savings

- Confidence maintaining your vehicle and fixing future issues

Professional Electronic Throttle Control Testing Explained

While DIY diagnosis is possible, understanding what professional testing entails helps determine if dealership diagnosis makes sense for your situation.

Here is an overview of trained throttle diagnostic processes:

Electronic Throttle Body Tests

- Scan ECM for diagnostic trouble codes pointing to electronic throttle failure

- Connect voltmeter to throttle position sensor electrical connector and compare voltage readings to factory spec with throttle completely closed and wide open

- Watch RPM gauge or scan tool sensor data while manually operating the throttle body linkage to test for binding or erratic readings

- Test continuity of throttle motor windings for any opens or shorts indicating component failures

Accelerator Pedal Sensor Tests

- Scan for any accelerator pedal position (APP) sensor codes

- Move pedal smoothly through its range while watching APP sensor voltage change values as expected per factory specifications

- Perform continuity tests on pedal position sensor connector wires to check for damage or shorts

These advanced tests combined with mechanic training pinpoint if the throttle body, TPS, accelerator pedal sensor require replacement – or if there is an underlying engine performance issue to address first.

Throttle Body or Throttle Position (TPS) Sensor DIY Replacements

Once diagnosed, the most common fix for electronic throttle control issues is replacing the:

- Throttle body assembly

- Throttle position sensor

Thankfully both are designed for routine maintenance and DIY replacement. Here are step-by-step instructions to safely change either part in your vehicle:

Throttle Body Replacement

Supplies Needed:

- New throttle body for your specific engine

- New gaskets to mount and seal throttle component

- Throttle body cleaner spray if reusing coolant hoses

- Standard socket set and screwdriver

- Torx bits to remove special throttle body screws if required

- Disconnect Negative Battery Terminal – Disconnect the negative battery cable from your battery to cut all power during the procedure.

- Remove Air Intake Components – Your throttle body receives air flow from your air filter housing. The intake setup must come off to access the throttle component. Save removed clamps and hardware.

- Disconnect Electrical Connector – Unplug the electrical harness leading to the throttle body motor. Also disconnect any supplemental hoses like the cooling line.

- Remove Mounting Screws – Locate and remove the two or three fasteners holding your throttle body to the intake manifold. Support it from falling once loose.

- Install New Throttle Body – Carefully install the new throttle component and hand tighten mounting screws. Reconnect electrical harness and any disconnected hoses at this time, replacing gaskets.

- Reinstall Intake – Attach cleaned air intake components in reverse order back onto throttle body. Double check everything is tight.

- Reconnect Battery – Restore your battery connection. Start engine and test for normal operation.

Following throttle body manufacturer instructions for your specific vehicle avoids missing any important nuances on installation. Always consult a factory service manual if any questions arise.

Throttle Position (TPS) Sensor Replacement

Supplies Needed:

- New throttle position sensor for your vehicle

- Basic hand tools like sockets, ratchet, and screwdriver

- Digital multimeter for testing

TPS Sensor Replacement Steps:

- Disconnect Battery Ground Cable – Safely remove negative terminal connection before beginning.

- Locate Sensor – Find the throttle position sensor typically on top or side of the throttle body. Some vehicles position it near the pedal assembly under the dash.

- Remove Mounting Screw(s) – Carefully remove sensor retaining screws. Note some sensors have special tamper proof screw heads requiring special tools.

- Disconnect Sensor Harness – Unclip the TPS electrical connector from the sensor itself. Take care not to damage connector.

- Compare Old and New Sensors – Carefully observe old sensor mounting and positioning before removal so the new direct fit unit installs properly.

- Install New TPS Sensor – Place the new TPS sensor into position and reinstall mounting screws to factory torque specs where possible.

- Reconnect Sensor Harness – Plug the electrical connector back into the top or side of the new TPS sensor. listened for an audible click.

- Reattached Battery Cable – With the new sensor installed, safely reconnect battery ground cable.

Start the vehicle and allow engine to fully warm up. Then compare sensor voltage readings at closed throttle and wide open positions to factory specifications. Values should sweep smoothly as you slowly depress the pedal showing your new sensor works properly.

What if Throttle Components Test Good but Issue Persists?

While checking a faulty electronic throttle body or TPS sensor are common DIY repairs – what steps should you take if replacing both doesn’t alleviate your acceleration issues?

- Double check all electrical harness connections are tight with no visible damage

- Test battery voltage and connections ensuring strong 12+ volt supply to components

- Inspect accelerator pedal and mechanism for smooth movement from stop to full travel range

- Review trouble codes and confirm throttle related ones cleared after the replacements

- Scan other engine control module sensors to check for additional failures like crankshaft position sensor or fuel pressure problems.

Seek professional diagnosis if throttle symptoms continue even after replacing both electronic throttle body and TPS units. There may be an underlying engine performance issue the mechanic can detect with further testing. Their specialized diagnostic computers see sensor data you cannot access with basic code readers.

Protecting Throttle System Longevity with Maintenance

While electronic throttle components can eventually just fail from age and miles, following some best practice maintenance steps promotes long lifespan:

- Follow Factory Recommended Service Intervals – Especially for throttle body cleaning every 75,000 to 90,000 miles on average. This prevents sticky buildup disrupting throttle plate movement.

- Change Air Filters – Dirty clogged air filters negatively impact air intake sensors like the mass airflow (MAF) sensor – causing throttle functionality issues over time.

- Address Check Engine Light Codes Promptly – Ignoring throttle related engine trouble codes allows sensor damage to spiral out of control into bigger system failures.

- Buy Quality Gas – Low quality dirty fuel leads to carbon build up on delicate electronic throttle components – accelerating wear and tear over their design life.

Making throttle maintenance just as high a priority as changing oil keeps your acceleration system responsive for the long run. Check your owner’s manual for any other throttle specific intervals for your vehicle.

Conclusion – An Empowering Throttle Control Repair Understanding for DIYers

Electronic throttle systems seem mystifying at first when acceleration issues creep up. But arming yourself with knowledge of how throttle control works, potential failure symptoms, and viable at-home diagnostic options shrinks complexity down to manageable size.

Noticing early warning signs like stalling, rough idle, or check engine lights avoids spiraling into full functional failures stranding your vehicle. Starting DIY diagnosis helps determine if replacing the throttle body or throttle position sensor yourself restores function at major cost savings. Or alternatively gives you the information for a more targeted professional repair if engine issues run deeper.

Either path returns your acceleration and throttle response back to normal reliability. This prevents having to limp it along never quite sure when symptoms might spike unpredictably.

With an empowering beginner’s understanding of electronic throttle control systems – a little sensor failure doesn’t have to slow you down thanks to informed repair or replacement choices personally restoring performance. Your vehicle’s acceleration depends on you making throttle upkeep just as high a priority as brake, engine, or transmission work.

What tips would you add around electronic throttle testing and repair from your own DIY experience? Share your input below in the comments to help other readers!