Can Am Outlander 570 ATVs Problems: Fixed!

The Can Am Outlander 570 is one of the most popular mid-sized ATVs thanks to its powerful Rotax V-twin engine, smooth handling, and rugged construction. With proper care and maintenance, an Outlander 570 can provide years of reliable recreational riding and utility use. However, like any machine, issues can develop over time that affect performance and drivability.

What are the most common problems Outlander 570 owners deal with and how can you diagnose and fix them yourself?

Issues like difficult starting, loss of power, overheating, electrical gremlins, and engine noises are frequently reported. With some basic mechanical skills and troubleshooting, many common Outlander 570 problems can be repaired at home.

This article will provide an in-depth look at the most prevalent issues owners experience with the Can Am Outlander 570 ATV along with troubleshooting tips and repair procedures for each problem. Specific problems covered include:

- Hard starting or complete failure to start

- Loss of engine power

- Overheating

- Electrical issues

- Engine noises like knocking or ticking

Understanding the origins and solutions for these common problems will help keep your Outlander 570 running strong for years to come. Let’s start by examining the most frustrating issue of all – when the engine refuses to start at all.

Table of Contents

Hard Starting or No Start Problems

Nothing is worse than turning the key on your Outlander 570 and getting nothing in response. Between the battery, ignition components, fuel delivery system, and engine compression, there are a number of reasons why your ATV may fail to start or struggle to turn over. Here are the most common culprits and how to diagnose them:

Check the Battery Charge and Connections

The first thing to check whenever your Outlander 570 won’t start is the condition of the battery. Using a voltmeter, check that the battery is charged to at least 12.5 volts. If it reads lower, try recharging the battery and testing again.

Inspect the battery terminals and cables for any corrosion, damage, or loose connections that could impede power transfer. Clean the terminals and cable ends thoroughly with a wire brush or baking soda solution to remove any deposits. Tighten all connections and make sure the cables are securely attached to the battery posts.

If cleaning and recharging the battery does not resolve hard starting issues, it may be time to replace the battery entirely. Batteries typically last 3-5 years before starting capacity diminishes.

Inspect the Spark Plug

The next critical thing needed to start your engine is proper ignition spark. Remove the spark plug and examine its condition. Look for any signs of heavy carbon deposits, oil fouling, damaged electrodes, or excessive wear indicating the plug needs replacement. The spark plug should have light gray or brown coloration on the insulator.

While you have the plug out, try testing for spark by reinstalling the plug into the cap and grounding it to the engine case. Have a helper crank the engine while you check for a blue spark at the electrode tip. If there is weak or no spark, there could be an issue with the magneto ignition coil, stator, or CDI unit.

Installing a fresh, properly gapped spark plug can help resolve ignition-related hard starting issues. Use the recommended NGK DCPR8E plug or equivalent.

Check Fuel Delivery

The engine needs fuel as well as spark for combustion and starting. Make sure your gas tank has fresh fuel and the fuel petcock is turned to the on or reserve position so fuel can flow from the tank to the carburetor or fuel injectors.

Check for any clogs or restrictions in the fuel lines that may impede flow. Also, inspect the fuel filter inside the tank – if it looks very dirty, replace it with a new one so fuel system contaminants don’t block the injectors.

For carbureted Outlander 570 models, check the float bowl for proper fuel level and make sure the carburetor is getting fuel when the accelerator is pumped. Spray starter fluid into the carb throat while cranking to test for fuel delivery issues.

For fuel injected models, listen for the whine of the fuel pump as the key is turned on. No noise indicates a bad fuel pump. You can also test fuel pressure directly at the fuel rail. Lack of pressure points to a faulty pump or clogged filter.

Verify Engine Compression

In addition to spark and fuel, engines require good compression for starting and running. Using a compression tester in the spark plug hole, test and record the compression reading for each cylinder. A reading under 100 PSI indicates worn piston rings, cracked cylinder walls, leaking valves, or a blown head gasket.

Low compression on one cylinder points to issues on that cylinder. Low readings across multiple cylinders typically indicates a problem with the head gasket. High mileage engines may need an engine rebuild if compression is very low.

Check Other Electrical Components

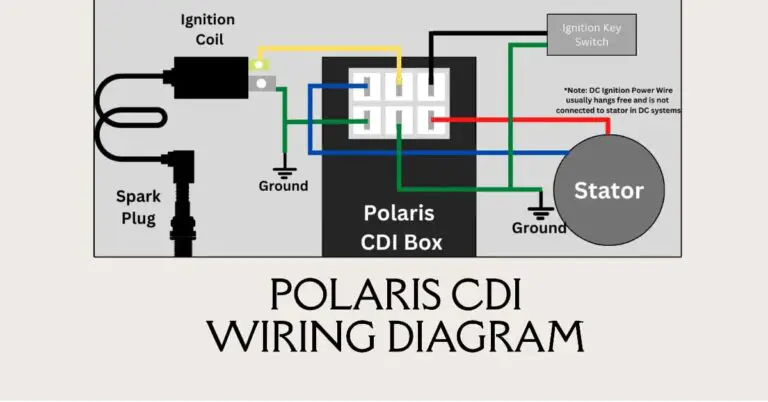

If the battery, spark plug, and fuel system check out, the issue may lie in the Outlander’s magneto ignition components. On some 570 models, the stator can fail causing no spark. The CDI box generates the spark timing signal so a faulty unit can also lead to hard starting.

Check all ignition related wiring harnesses and connections for any corrosion, damage, or loose plugs. Clean and reconnect anything that looks questionable. If you suspect issues with the stator or CDI, replacing those components may be required.

Following this structured troubleshooting approach should allow you to get to the bottom of starting problems on your Outlander 570. Pay special attention to basic factors like battery condition, spark, fuel, and compression first before moving to electrical gremlins.

Loss of Engine Power

The Can Am Outlander 570 produces around 44 horsepower from its 569cc Rotax V-twin engine. This muscular power makes quick work of tough trails and heavy loads. But over time, lackluster engine performance can become an issue that drains the fun from your rides. There are a handful of common problems that can result in significant power loss:

Clogged Air Filter

ATVs generate a lot of dust and dirt when riding on trails and back roads. Much of this debris gets sucked into the air filter where it can eventually congest the filter element and restrict air intake. Lower airflow chokes the engine, reducing power output.

Check your air filter after every few rides and clean or replace it periodically. Use compressed air to blow out the filter, or wash foam filters with mild soap and water. Be sure the filter is completely dry before reinstalling. Replace very dirty filters.

Proper air filter maintenance is one of the easiest ways to keep your Outlander 570 running strong. Don’t neglect this first step when experiencing power loss issues.

Fuel Delivery Problems

Lack of fuel prevents the engine from producing full power. As discussed in the no-start issues section, make sure fuel is able to flow from the tank through the lines and filters to the carburetor or fuel injectors. Listen for the in-tank fuel pump when the key is switched on.

Check fuel lines for cracks or obstructions. Ensure the petcock is allowing fuel through. Replace dirty fuel filters. Clean carburetors if the float bowl is full of gunk. Test injectors for proper spray patterns and volume. Address any fuel system issues to restore power.

Fouled or Malfunctioning Spark Plug

The spark plug initiates the air-fuel combustion inside the cylinder. So problems here can diminish power. Inspect the plug for heavy carbon deposits indicating a rich fuel mixture. The insulator tip should be light brown, not blackened. Replace excessively worn or oil fouled spark plugs.

Ensure the spark plug gap is set correctly at 0.7-0.8 mm. Wider gaps can result in weak sparks and misfires under load. Check for good blue spark by testing with the plug grounded to the cylinder head.

Clogged Fuel Injectors

The high-pressure fuel injectors atomize and spray gasoline into the cylinders. On fuel injected Outlander 570 models, dirty injectors with restricted openings hinder fuel delivery, reducing engine output.

You can test injector flow and pattern by cranking the engine with the air filter removed and watching the fuel spray. Poor flow or irregular spray indicates fouled injectors. Injector cleaning chemicals exist but replacement may be needed for very dirty units.

Throttle Body Issues

The electronic throttle body controls airflow into the engine based on rider throttle input and commands from the ECU. Oil, dirt, and carbon buildup inside the throttle body can restrict air intake similar to a clogged air filter.

Cleaning the throttle body bore and plate with throttle body cleaner spray can restore responsiveness and power if excessive grime is present. Also inspect the throttle position sensor and any air intake hoses for blockages.

Engine Wear

As an engine accumulates miles and hours, normal wear on internal components like rings, bearings, valves, and cylinder walls reduce efficiency and power. Compression starts to drop as the pistons no longer seal tightly against the cylinders. Valve timing goes out of tune.

If your Outlander 570 has very high mileage or hours, worn out engine internals may be behind power loss. Checking compression and leak down can indicate the extent of wear. At some point, rebuilding the top end or entire motor becomes necessary.

Following good maintenance like air filter care, spark plug replacement, and fuel system inspection will help your 570’s engine run peak performance for longer. Adjusting valve clearance as needed and using quality oil & fuels also promotes longevity.

Overheating Problems

Allowing your Can Am Outlander’s engine to overheat can lead to serious mechanical damage and breakdowns out on the trail. Here are some of the leading causes of ATV overheating along with tips to resolve the issues:

Radiator Blockage

The radiator on the Outlander relies on good airflow to cool the antifreeze and engine. Mud, debris, and bent fins can all obstruct airflow leading to overheating. Carefully clean the radiator by spraying water or compressed air from the engine side and gently straightening any bent fins with a butter knife.

Prevent future blockages by installing a radiator guard screen to deflect some debris. Regularly inspect and clean the radiator to maintain cooling capabilities. Take care not to damage the delicate fins during cleaning.

Low Coolant Levels

The radiator and coolant overflow tank should be filled to the proper level with a 50/50 mix of antifreeze and distilled water. Check coolant levels cold before each ride. Top up if low as coolant provides vital cooling and corrosion protection.

Signs of leaks include coolant puddles under the ATV, white exhaust smoke, bubbling overflows, and rapid coolant loss. Fix any leaks in the radiator, hoses, water pump seals, or head gaskets to prevent overheating.

Pressure test the cooling system annually for leaks. Flush contaminated or old coolant to maintain ideal antifreeze properties. Use high quality coolant rated for aluminum engines.

Water Pump Failure

The water pump circulates coolant through the engine and radiator. Bad bearings, broken impeller shafts, and worn impeller seals can all lead to pump failure and reduced coolant flow.

Inspect the pump visually for leaks or shaft play. Feel the radiator hoses with the engine running to verify hot coolant is circulating during operation. Replace faulty water pump components or the complete pump as needed.

Thermostat Issues

The thermostat controls coolant flow and engine temperature. A stuck closed thermostat prevents coolant from reaching the radiator leading to overheating. Remove and visually inspect the thermostat – thermal wax should be visible inside when opened.

Test the thermostat by placing it in boiling water on the stove. It should fully open at the proper temperature. Replace any faulty thermostat to maintain proper engine operating temperatures.

Fan Malfunctions

Electric cooling fans mounted in front of the radiator improve air flow at low speeds or when stopped. Malfunctioning fans that fail to switch on can lead to boilovers on hot days. Test fan operation directly by applying 12V power. If unresponsive, check wiring and fan relay or replace the fan motor itself.

Keeping your Outlander 570’s cooling system well maintained and promptly addressing overheating issues will allow worry-free operation even on the hottest summer trail rides. Monitor engine temps closely and stop immediately if readings climb too high.

Electrical Problems

Like most modern ATVs, the Can Am Outlander 570 utilizes various electrical components and sensors to control critical engine management and drivetrain functions. Issues with wiring, connectors, switches, or electronics can lead to performance problems or complete breakdowns.

Electrical issues often produce the most frustrating and intermittent gremlins. Here are some tips for tracking down common electrical failures on your Outlander.

Battery Terminal Corrosion

While discussing hard starting problems earlier, it was noted that corroded battery terminals can cause intermittent power delivery issues. The terminals should be cleaned regularly with a wire brush to remove any white, green, or blue corrosive build up.

Apply dielectric grease to the terminals after cleaning to prevent future corrosion. Check where the battery cables bolt onto the battery posts – these connections also corrode over time.

Damaged Wiring Harnesses

The many wiring harnesses threading through the frame to connect sensors, lights, and electronics can chafe and short out over time. Inspect the routing of all visible harnesses looking for any rubbing, cuts, loose plugs, or damaged insulation.

Pay particular attention to spots where wires pass through holes or may contact sharp frame elements. Repair damaged sections with electrical tape and consider rerouting or protecting harnesses as needed.

Faulty Electrical Connectors

Numerous multi-pin electrical connectors link the various Outlander components together. Corrosion on the pins inside these connectors can interrupt signals causing electrical faults.

Spray out dirty connectors with electrical contact cleaner. Apply dielectric grease to the contacts to prevent future corrosion. Ensure connectors lock together firmly and check for bent or loose pins. Replace damaged connectors or terminal pins as needed.

Stator Failure

The stator is essentially a set of wire coils inside the engine that generate electricity to power the CDI unit, electronics, and charge the battery. Over time, the stator windings may weaken and output lower voltage leading to electrical issues.

Test stator output by measuring AC voltage at the stator leads with the engine running. Compare to factory spec – too low of a reading indicates a bad stator that must be replaced.

CDI Unit Problems

The capacitor discharge ignition (CDI) box produces the high voltage needed to generate spark for starting and running the engine. Faulty CDI units can cut spark intermittently or on certain cylinders leading to misfires.

If you suspect CDI troubles, swap in a known good unit from another Outlander and test. Check that CDI connectors are clean, dry, and undamaged. Replace the CDI completely if determined to be the root cause.

Electrical problems often require systematic testing of circuits and components to isolate the specific fault. Having a service manual with wiring diagrams and specs aids diagnosis. Don’t rule out more than one issue – a faulty CDI combined with corroded battery cables for example.

Engine Knocking and Ticking

Metallic knocking or ticking noises emanating from the engine are never a good sign. While some noise is normal during cold startups, chronic knocking indicates a problem. Here are some likely causes of Outlander 570 engine knocks:

Detonation from Low Octane Fuel

Using a lower than recommended octane gasoline can cause damaging detonation and pre-ignition engine knocks under load. Always run at least 87 octane gas in the Outlander as specified by the manufacturer.

Higher octane fuels resist pre-ignition better and are preferred for high performance applications. See if knocking improves after filling up with a quality 91+ octane fuel. Ethanol blends are also more knock-prone than pure gasoline.

Excessive Valve Clearance

To maintain performance, the valves on the 570 motor need periodic adjustment as clearance increases with use. Excessive lash in the valve train allows valves to open and close violently, causing ticking noises and potential damage.

Check and adjust valve clearance on the Outlander per the service manual specs. Tighten down any loose rocker arms or replace worn parts in the valve train as needed to quiet operation.

Low Oil Levels

Letting the crankcase oil level fall too low allows metal-on-metal friction during engine operation leading to knocks and wear. Always maintain proper oil level on the dipstick and change oil according to the maintenance schedule.

Engine oil provides critical lubrication, cooling, and protection for internal components. Never ignore low oil pressure warning lights. Revving the engine very high with insufficient oil causes metal damage.

Worn Bearings and Pistons

With enough accumulated operating hours, engine bearings, piston pins, piston rings, cylinder walls, and other internals wear to the point of inducing knocks and loss of performance. You may notice power fall off accompanied by loud lifter noise.

If bearing shells or inserts look heavily scored when inspected, a full engine rebuild will be needed to restore proper running condition. Similarly, pistons with excess ring gap, scuffing, or scoring mean a top end rebuild should be performed.

Persisting engine knocks and ticks always warrant further investigation via compression testing, leak down checks, and internal inspections. Addressing the root causes promptly reduces the chances of permanent engine damage.

Conclusion

While the Can Am Outlander 570 is one of the most reliable mid-sized ATVs available, common issues can develop over time. Difficult starting, loss of power, overheating, electrical gremlins, and engine noises are problems most owners will contend with at some point.

Fortunately, many of these issues can be diagnosed and repaired yourself with some mechanical knowledge and troubleshooting experience. Focus on basics like battery, air, fuel, and spark when troubleshooting hard starting problems. For loss of power, check air filter, plugs, fuel delivery, and intake components first.

Keep up on routine maintenance and address problems promptly to maximize longevity. Follow the troubleshooting tips provided and your Outlander 570 should continue delivering years of off-road fun and utility use.